65 King Street / Google Office – Toronto

Industry: Office Tower

Application: Office building

Highlights:

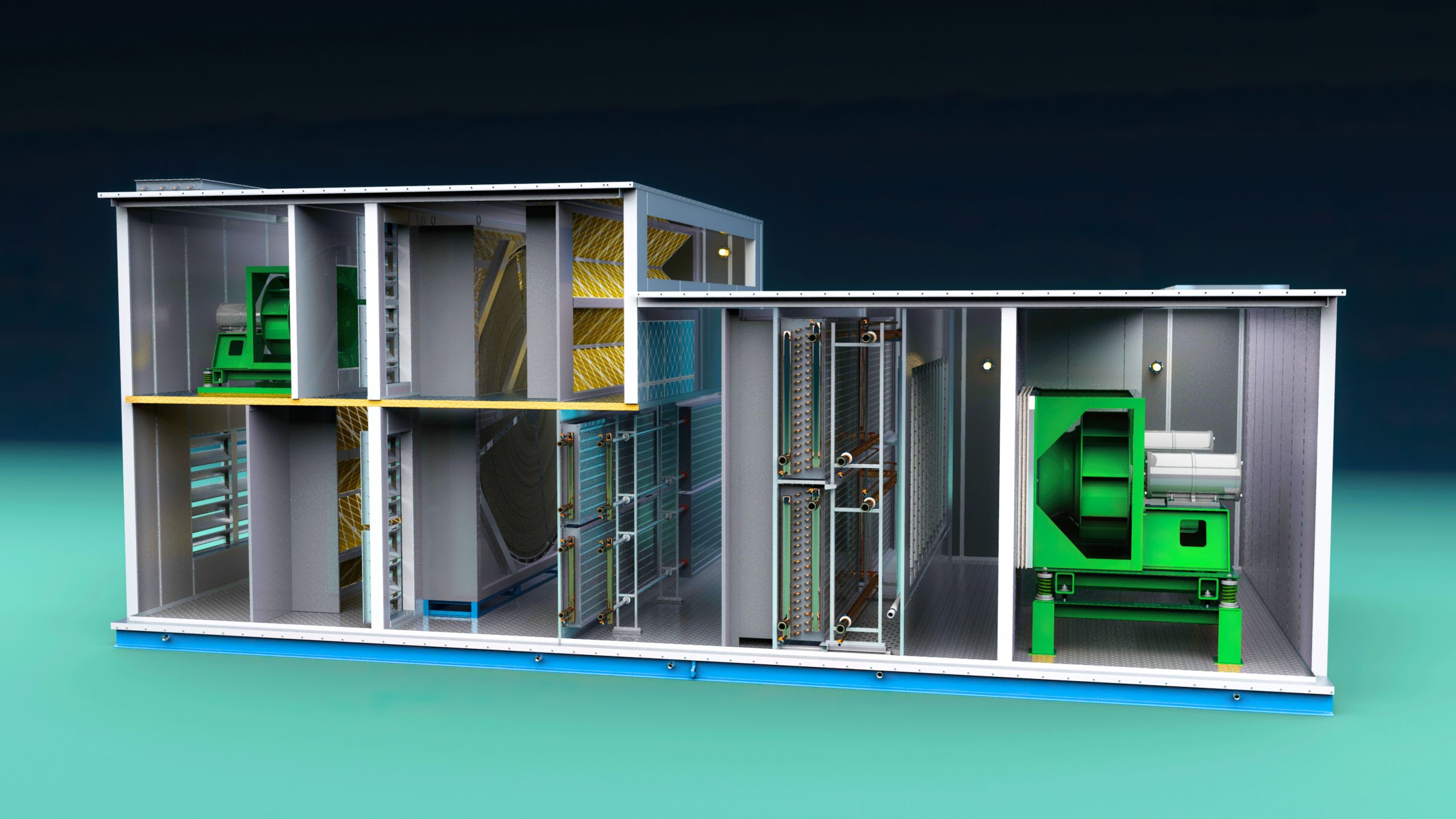

Compartment units:

- Floor by floor units provided in the core of each floor of the tower

- Floor by floor compartment down flow air handling units

- Ultra high efficiency and low noise Acoustiflo fans with integral silencers

- Welded aluminum airfoil fan wheels.

- Internal spring isolation for elimination of fan vibration transmission to building

- Low internal air pressure drops to minimize energy usage

- Integral floor stands to mate with underfloor distribution system

- Four inch high density insulation and perforated liners for maximum sound absorption

- Fire and smoke rated insulation for building and occupant safety

- Heavy gauge steel casing panels for minimum sound transmission

- White painted exterior for bright mechanical room.

- Cooling coil bypass damper for humidity control

- Chilled water cooling coils with stainless steel racks

- Stainless steel recessed and sloped IAQ drain pans

- Aluminum airfoil dampers

- Internal lighting

- Doors with inspection windows, chrome plated handles, and automotive grade bulb seals

- Welded aluminum checker-plate floors

- MERV 13A filtration

- Integral recessed filter air pressure drop gauges

Outside air heat recovery units

- Enthalpy wheel heat recovery with SGA Hi Pannex media for maximum sensible and latent recovery and minimum cross-contamination

- Aluminum airfoil bypass dampers with hexagonal linkages on heat wheels to minimize air pressure drop when heat recovery is not needed.

- Heavy duty welded structural heat wheel cassette with long life bearings

- Angled exhaust filters to minimize unit height

- Stepped unit geometry and variable component velocities to minimize unit height for available space.

- Stainless steel cooling coil racks and sloped IAQ drain pans

- Staggered coil racks to allow for same side pull and connection but minimize space required for coil pull

- Factory installed coil connection extensions for internal coil with thermal breaks to allow for pipe insulation.

- Short absorption humidifier manifolds

- Continuously welded aluminum checker plate floors with floor drains.

- High efficiency fans with welded aluminum airfoil wheels, centered in airstream to maximize performance

- Internally spring isolated fans with seismic restraints

- Short absorption distance stainless steel humidifier manifolds

HAAKON

Haakon Industries is a world leader in Custom Designed and Manufactured HVAC equipment. Our experienced Engineering staff strives to provide Excellent Quality and Service to ensure our client’s needs are met and exceeded.

ENGINEERING

All units are designed and engineered from our head office in Richmond, BC allowing for focused engineering solutions and consistent quality.

MANUFACTURING

Manufacturing is supported by three factories; Richmond, BC, Cheney, WA, and Kingston, ON. Utilizing a wide range of materials and diverse suppliers, each component is custom made for the specific unit; from access doors to fanbases.

Each factory leverages state of the art equipment to ensure the highest level of quality and each unit undergoes an extensive quality control unique to each and every unit.

INDUSTRIES + APPLICATIONS

We create a wide variety of air handling units for applications as different as night and day. Some of our most common design challenges are meeting the dimensional requirements, serviceability needs, and unit efficiency.

Haakon Industries

11851 Dyke Road,

Richmond, BC, Canada

V7A 4X8

Phone: 604-273-0161

Fax: 604-273-8397